- La FORCE ONE de CELO llega a la cima

- The complete guide to concrete screws

- Accesorios para Clavadora de gas FORCE ONE+

- Homologación ETA para el sistema FORCE ONE

Contacto oficina técnica

Lunes a Jueves de 8.00 h -18.00 h

Viernes de 8.00 h -17.00 h

+1 786 609 8127

ContactarThe complete guide to concrete screws

1. Definition: What is a concrete screw?

2. Main applications: When should you use a concrete screw?

3. Mounting: Install concrete screws in just three steps

4. Head types: Which concrete screw is the best for my application

5. Assortment: What concrete screws can CELO offer you?

6. Concrete screw FAQs

1. Definition: What is a concrete screw?

Just like a wood screw is to wood, concrete screws provide a quick and easy way to fasten to concrete whilst providing strong load values. They are an easy method of installation as they are directly screwed into the concrete and unlike other traditional installation methods, you do not have to do any hammering! All you need to do is drill a hole, clean the hole and drive in the screw.

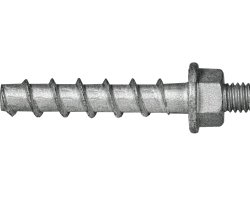

They have a serrated cutting thread that will cut their way into the concrete as they are screwed in, providing a tight and secure fixing.

2. Main applications: When should you use a concrete screw?

Concrete screws are typically used in heavy-duty applications. Most concrete screws come with a range of approvals and certifications such as ETAs, including fire resistance tests and seismic approvals, meaning you can use the screws in many different applications in both cracked and non-cracked concrete.

Typical concrete screw applications:

- Ventilation systems

- Sanitary installations

- Electrical installations

- Fastening rails

- Cable trays

- Attaching steel structures

- Rails and supports

- Fences

- Clamps

3. Mounting: Installing concrete screws in just three steps

Installing with concrete screws are one of the easiest and quickest ways to install on concrete and can be achieved in 3 easy steps.

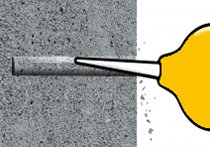

Step 1: Drill hole

Step 2: Clean out hole

Step 3: Drive in the screw!

Although the installation process is quite simple it is important to ensure the correct installation procedures are followed in accordance with the ETA. This includes ensuring you always clean out the hole, using the correct amount of torque and not overtightening the screws.

We have created a series of installation videos for some of our most popular concrete screw products, to help demonstrate the installation process and application uses.

https://youtu.be/C6iqCJD0Wdw View more videos

4. Head types: Which concrete screw is best for my application?

There is a large variety of concrete screws available with different head types, designed for different applications, that come in various sizes and materials. Below we take a look at the main head types available to suit different applications:

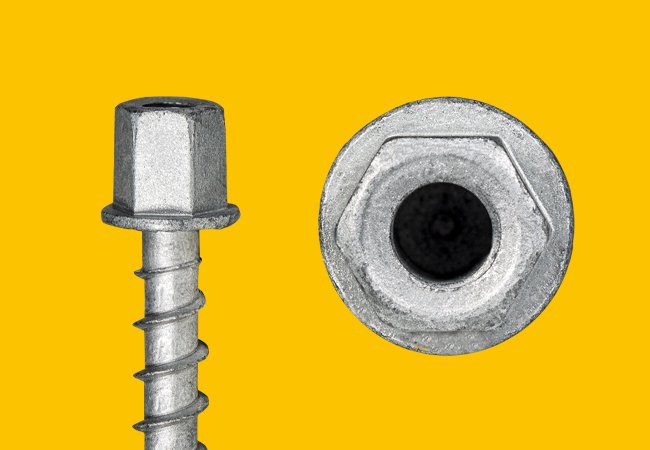

HEX HEAD

The hex head screws come with an integral washer and are suitable in applications where the design of the head of the screw can protrude the surface of the item being fastened. The head allows for easier driving and tightening of the screw.

Applications:

- Railings

- Metal profiles

PAN HEAD

The design of the pan head allows for a flush finish against the fastening application, meaning it can be used in a wider variety of applications. Its flatter head means that there is less strength when tightening compared to the hex head.

Applications:

- Railings

- Channels

CONNECTING THREAD

The connecting thread allows for direct installation of the application and is easy to install reducing installation time especially when installing overhead.

Applications:

- Pipe clamps

- Rails

- Channels

INTERNAL THREAD

A fast alternative to the drop-in anchor, concrete screws with internal thread are perfect for ceiling installations and allow for direct installation of the application.

Applications:

- Pipe clamps

- Rails

- Channels

5. Assortment: What can CELO offer?

We offer a wide range of concrete screws for many different applications. Most of the screws in our BTS range have undergone a wide range of tests and are ETA-approved including fire resistance values, therefore meeting the high quality and safety requirements of the European market. Some screws also offer seismic options. Please check the technical data of each screw.

Below is a quick overview of our different product categories. To see the full product range please download our catalogue and leaflets.

BTS

Suitable for a wide range of heavy-duty applications. The BTS range is available in 3 setting depths and various materials.

BTS M

Designed for use in temporary construction sites. The BTS M should be used for temporary fixings and can be re-used several times.

BTS5

BTS5 requires a small drill hole and low setting depth, meaning a low screw-in force is required. Holds loads of up to 80kg in concrete.

BTS6

BTS6 comes in a variety of different head types to allow for a wide range of installations. Suitable for medium load applications.

6. Concrete screw FAQs

Can you use a regular drill to drill into concrete?

A hammer drill is recommended when drilling into concrete. The hammering motion helps break down the concrete while the drill rotation creates the hole.

What other names are given to concrete screws?

Concrete screws may also be called concrete anchors, concrete fasteners, or in the USA they are often called by the brand name Tapcon screws.

Can you screw directly into concrete?

Concrete screws are a quick and easy way of fastening to concrete, they do not require hammering like other fasteners. All you need to do is drill a hole, clean it out and drive in the screw, which we recommend doing with an impact wrench.

The drill hole depth and diameter will on the size of the concrete screw being used. Please consult the guide, especially when keeping in line with ETA approvals.

Are concrete screws removable?

All concrete screws can be removed if necessary. This is perfect for when a project changes and fixtures need to be moved. The BTS M for temporary construction site facilities can even be reused.

Which concrete screw should I use?

CELO has a wide range of concrete screws to choose from. If you are having difficulties deciding which one would work best in your applications then we have a specialised technical team to help you with any questions or advice.

Do concrete screws need plugs?

No. Concrete screws are directly screwed into the pre-drilled hole.

Do you need help understanding which concrete screw would be best for your application?

Do you need further details about loads, approvals or technical advice?

Can our sales representative visit and assist you?

Then please reach out to our customer service! We will be happy to help you!